Introduction

The document provides an overview of sensor integration to Astra MCU SDK software. For choosing appropriate sensor settings, understanding of Image Proc and Image Sense path is necessary.

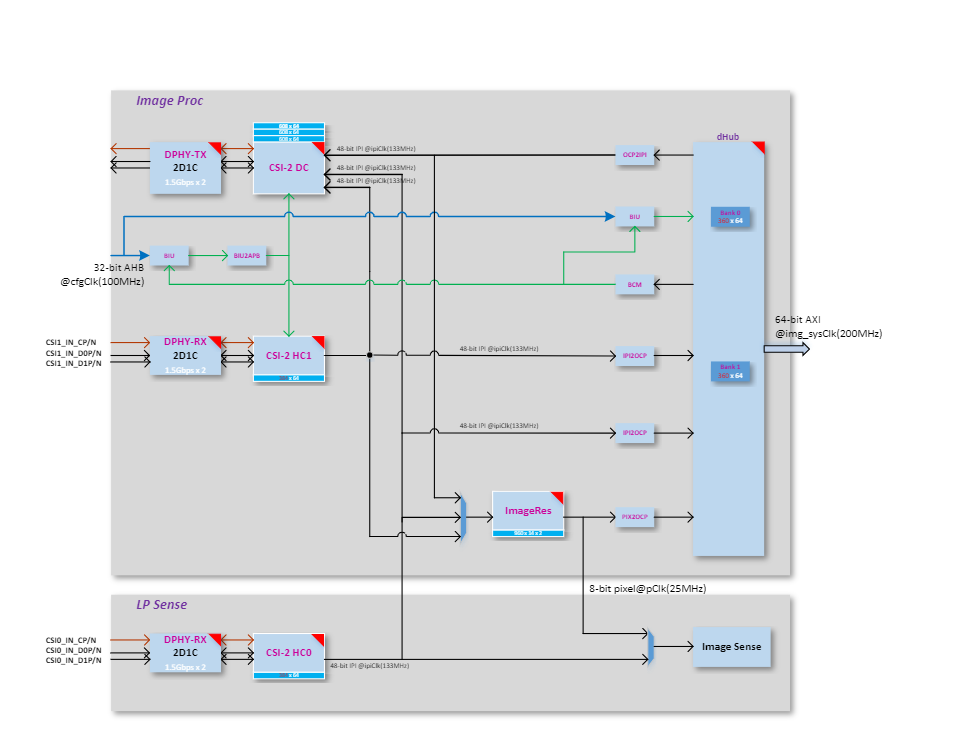

Figure 1‑1 depicts the high-level block diagram of Sabre CSI controllers connected to Image Proc / Image Sense path. The top block depicts different blocks within Image Proc, second block depicts CSI host controller feeding Image Sense pipeline. The capabilities of Image proc / Image Sense block play a key role in choosing the sensor.

Figure ‑ ImageProc-high level block diagram

Sabre Capability

CSI Host controller

Max number of lanes per CSI host = 2

Max data lane rate = 1500 Mbps per lane

Pixel bit depth = 8 or 10 bits.

Raw bayer / Monochrome/ RGB / YUV.

ImageProc

Operating clock = 133 MHz

LP Sense

Operating clock = 25 MHz

Sensor Clock

Sabre Clock Out = 24 or 19.2 MHz

Note: Other clock configuration possible and depends on Sabre PLL configuration.

Sensor Capability

To port the camera sensor, the following parameters must be checked and compared against CSI & LP Sense capability:

MIPI Clock Mode: continuous or non-continuous mode.

Num of lanes.

Pixel Depth.

Frame Rate.

Frame width and Height (include blanks).

Or

Width and Height (without blanks).

Sensor Clock frequency.

MIPI clock rate.

Table ‑ MIPI Clock Calculation

PixelRate = FrameWidth * FrameHeight * fps MIPI Bandwidth = PixelRate * Bits_per_pixel Datarate per lane = MIPI Bandwidth/number_of_lanes MIPIClkRate (differential) = Datarate_per_lane/2 |

|---|

Sensor Settings provided by Vendor: FrameWidth=2560 FrameHeight=2250 FrameRate = 30 PixelDepth = 10 PixelRate = 172.80000 MipiClkRate = 432.00000 Datarate per lane = 172.8*10/2 = 864Mhz |

Sensor Integration

Settings Selection

Based on the comparison below, pick up the appropriate settings from sensor vendor.

Compare Sensor’s MIPI Lane clock, lane, and bit depth capability against Sabre CSI host controller capability.

Check Sensor input clock’s requirement.

Sensor’s pixel rate must be lower than LP Sense clock (25Mhz) when CSI Host controller connected to LP sense path

Sensor’s MIPI Clock (MIPI Clock *2) must be less than or equal to 1500 Mbps per lane when CSI host controller connected to Image Proc path.

Sensor Addition

Follow the below steps to add a new sensor to Astra MCU SDK.

- Add sensor register settings folder to

common/components/ext_drivers/img_sesnors

Sensor registers folder contains source and include folder.

- In source folder, add sensor register file with different sensor

resolution / MIPI clock-based settings array provided by sensor vendor.

- In include folder, expose sensor specific array or function

prototype.

Enter Sensor index.

- Add sensor index (one for passthrough and another for sensing) to

sensors_types_e enumeration in common/components/ext_drivers/img_sesnors/common/include/img_Sensor_common.h

- Add sensor related array and functions to “entry_table_setting”

array.

3. In “sr100_ext_drivers.clayer.yml”, add new sensor files for compilation.

Sample Application

Sample Application (imgproc_demo_rx.c) supports pass-through and sensing with two different sensor configurations. Two different settings allow the user to perform the different operations.

Sensing with low resolution.

Pass through with higher resolution.

Sensing after downscaling.

Sensing while passthrough with low resolution.

Sensing after scale while passthrough with high resolution

Configuration

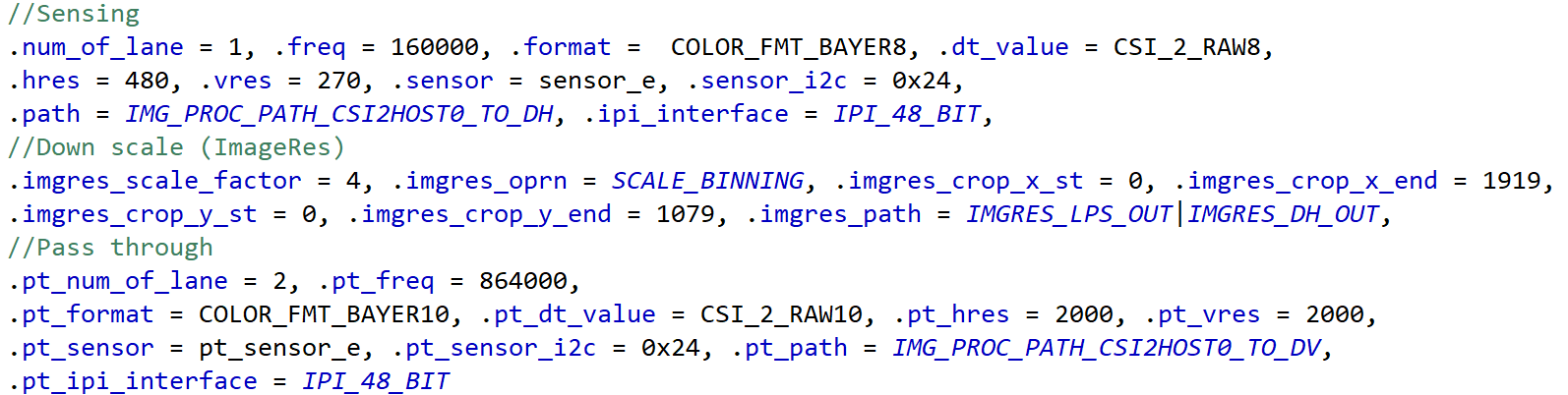

Add new config structure to sensor-based configuration array in sample application. Below structure configures Image Prop pipeline with Sensor parameters and Image Res parameters that depends on sensor frame size.

Select Sensor in “SENSOR_TYPE” Macro.

Edit HRES_MAX and VRES_MAX as per the width and height chosen for sensing. These 2 fields control the size of the frame being dumped to memory. Since Image Proc pipe writes frame width (HRES_MAX) as multiple of 24, align width but don’t edit other width in the configuration array.

typedef struct _img_config {

// Sensing Parameters

int num_of_lane; // Num of lanes

int freq; // MIPI Data rate per lane

int format. // Rx pixel depth

int dt_value; // Tx pixel depth

int hres; // Width (without blanks)

int vres; // Height (without blanks)

int sensor; // Sensor Index

int sensor_i2c; // Sensor I2C address

int path; // choose from image_proc_data_path_t

int ipi_interface; // 48- or 16-bit IPI interface

// ImageRes (Downscale) Parameters

int imgres_scale_factor; // Sub-Sampling or Binning factor

int imgres_oprn; // Sub-Sampling or Binning

int imgres_crop_x_st; // Crop Start X

int imgres_crop_x_end; // Crop End X

int imgres_crop_y_st; // Crop Start Y

int imgres_crop_y_end; // Crop End Y

int imgres_path; // Output to ImageProc/LP Sense path/both

// Pass through Parameters

int pt_num_of_lane;

int pt_freq;

int pt_format;

int pt_dt_value;

int pt_hres;

int pt_vres;

int pt_sensor;

int pt_sensor_i2c;

int pt_path;

int pt_ipi_interface;

}img_config;

typedef enum image_proc_data_paths{

IMG_PROC_PATH_CSI2HOST0_TO_DV = 0, // CSI Host-0 to CSI Tx in pass through mode

IMG_PROC_PATH_CSI2HOST0_TO_DH, // CSI Host-0 to memory in sensing mode

IMG_PROC_PATH_CSI2HOST0_TO_DH_DV, // CSI Host-0 to CSI Tx and memory

IMG_PROC_PATH_CSI2HOST1_TO_DV, // CSI Host-1 to CSI Tx in pass through mode

IMG_PROC_PATH_CSI2HOST1_TO_DH, // CSI Host-1 to memory in sensing mode.

IMG_PROC_PATH_CSI2HOST1_TO_DH_DV, // CSI Host-1 to CSI Tx and memory.

IMG_PROC_PATH_DHUB_TO_DV, // CSI Host-0 to CSI Tx and memory.

IMG_PROC_PATH_CSI2HOST0_TO_IMGRES, // CSI Host-0 to memory after down scale.

IMG_PROC_PATH_CSI2HOST1_TO_IMGRES, // CSI Host-1 to memory after down scale.

IMG_PROC_PATH_CSI2HOST0_TO_IMGRES_DV,//CSI Host-0 to memory after down scale and Tx(no scale)

IMG_PROC_PATH_CSI2HOST1_TO_IMGRES_DV, // CSI Host-1 to memory after down scale and Tx (no scale).

IMG_PROC_PATH_INVALID_LAST,

}image_proc_data_path_t;

Table ‑ Image Proc Configuration Example

SW Flow

Sensor Streaming Start

When the sensor operates in continuous clock mode, it sends a stop state signal only once i.e. before starts streaming. In such a case, MIPI data path must be started before sensor streaming because MIPI DPHY relies on stop state signal to trigger the internal calibration.

When the sensor operates in non-continuous clock mode, it sends a stop state signal at the end of frame data packets. In such case, MIPI data path can be started after or before sensor streaming.

Sample functions.

For verification of different use cases listed below, refer to imgproc_demo_rx.c

Sensing:

Capture Frame to System memory: vTaskMipiRxCamera

Capture Frame to memory after LP sense processing: vTaskImgProcToSense

Pass through: vTaskMipiPassThrough

vTaskMipiDataPathChange

Switching between Sensing and pass through

Sensing while pass through with / without Image Res (downscale) in path. Here incoming frame written to memory after downscaling while transmitting the same frame (without downscaling) to CSI Tx.

.

Copyright

Copyright © <<year or year span>> Synaptics Incorporated. All Rights Reserved.

Trademarks

Synaptics; the Synaptics logo; are trademarks or registered trademarks of Synaptics Incorporated in the United States and/or other countries. All other trademarks are the property of their respective owners.

Notice

This document contains information that is proprietary to Synaptics Incorporated (“Synaptics”). The holder of this document shall treat all information contained herein as confidential, shall use the information only for its intended purpose, and shall not duplicate, disclose, or disseminate any of this information in any manner unless Synaptics has otherwise provided express, written permission.

Use of the materials may require a license of intellectual property from a third party or from Synaptics. This document conveys no express or implied licenses to any intellectual property rights belonging to Synaptics or any other party. Synaptics may, from time to time and at its sole option, update the information contained in this document without notice.

INFORMATION CONTAINED IN THIS DOCUMENT IS PROVIDED “AS-IS,” AND SYNAPTICS HEREBY DISCLAIMS ALL EXPRESS OR IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, AND ANY WARRANTIES OF NON-INFRINGEMENT OF ANY INTELLECTUAL PROPERTY RIGHTS. IN NO EVENT SHALL SYNAPTICS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE USE OF THE INFORMATION CONTAINED IN THIS DOCUMENT, HOWEVER CAUSED AND BASED ON ANY THEORY OF LIABILITY, WHETHER IN AN ACTION OF CONTRACT, NEGLIGENCE OR OTHER TORTIOUS ACTION, AND EVEN IF SYNAPTICS WAS ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. IF A TRIBUNAL OF COMPETENT JURISDICTION DOES NOT PERMIT THE DISCLAIMER OF DIRECT DAMAGES OR ANY OTHER DAMAGES, SYNAPTICS’ TOTAL CUMULATIVE LIABILITY TO ANY PARTY SHALL NOT EXCEED ONE HUNDRED U.S. DOLLARS.

Ordering Information

For ordering information and a complete list of Synaptics’ products, contact your Synaptics sales representative. Visit our website at www.synaptics.com to locate the Synaptics office nearest you.

Contact Us

Visit our website at www.synaptics.com to locate the Synaptics office nearest you.